600 ton stainless steel sink hydraulic press machine Hydraulic Press Machine

Model No.︰600T

Brand Name︰Dingrun Forging

Country of Origin︰China

Unit Price︰US $ 215000 / SET

Minimum Order︰1 SET

Product Description

Stainless steel sink hydraulic press machine Hydraulic Press Machine

The main performance characteristics: Economical and Practical, Hydraulic press control adopts to insert set valve integrated system, decrease let out Point.Movement reliability, durable and long life span, Itis constant pressure to realize with calm in the first place and calm procedure two develop technology, have to insure press the function of delay time, The route of working pressure may be regulated in assigned scope, adopt buttons for centralized control, Can realization manual, Semi-automatic, automatic 3 operate form. Application field : This series of hydraulic press is suitable for the pressing process of plastic materials, such as stamping, bending, flanging and thin stretching, etc. It can also be used for the correction, press-fit, plastic products and powder products.

|

Specification |

Unit |

630T-A |

630T-B |

630T-C |

|

|

Nominal force |

KN |

6300 |

6300 |

6300 |

|

|

Max. pressure of liquid |

MPa |

25 |

25 |

25 |

|

|

Stroke of slider |

mm |

600 |

900 |

900 |

|

|

Max. opening height |

mm |

1200 |

1500 |

1500 |

|

|

Working table size |

mm*mm |

1200x1000 |

1600x1600 |

2200x1600 |

|

|

Speed of slider |

Descent speed |

mm/s |

120 |

120 |

120 |

|

Working speed |

mm/s |

5-12 |

5-12 |

5-12 |

|

|

Return speed |

mm/s |

90 |

90 |

80 |

|

|

Motor power |

KW |

22x2 |

22x2 |

22x2 |

|

|

Ejecting force |

KN |

100 |

100 |

100 |

|

|

Ejecting stoke (mm) |

mm |

300 |

300 |

300 |

|

|

Weight |

T |

18.5 |

22.5 |

23.5 |

|

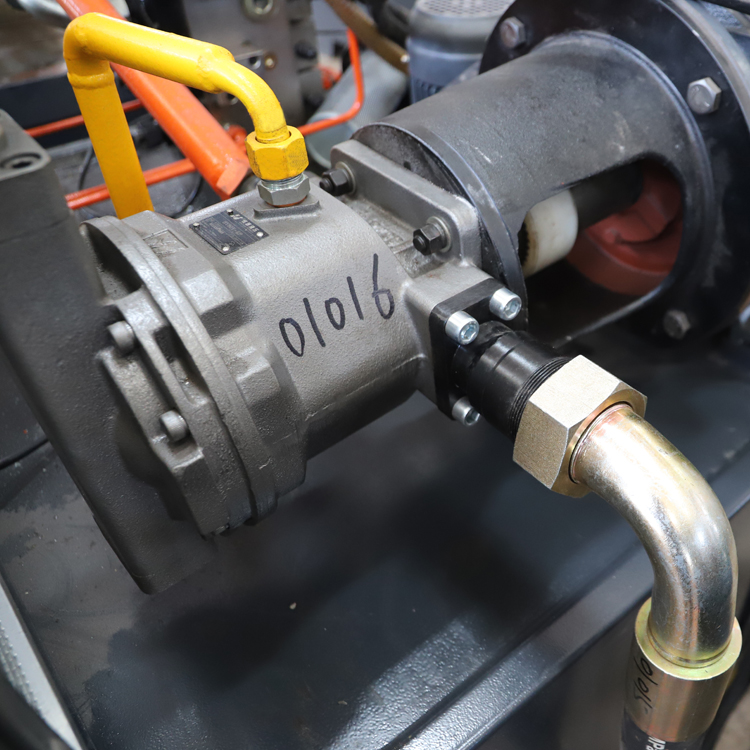

Hydraulic Press System: The hydraulic press system device is arranged on the right side of the press, with cartridge integrated system, flexible action, reliable work, good sealing performance. The hydraulic pump comprises an oil tank, a high-pressure pump, motor, cartridge valves and other components.

HYDRAULIC PRESS SYSTEM

The hydraulic system device is arranged on the right side of the press, with cartridge integrated system, flexible action, reliable work, good sealing performance. The hydraulic pump comprises an oil tank, a high-pressure pump, motor, cartridge valves and other components.

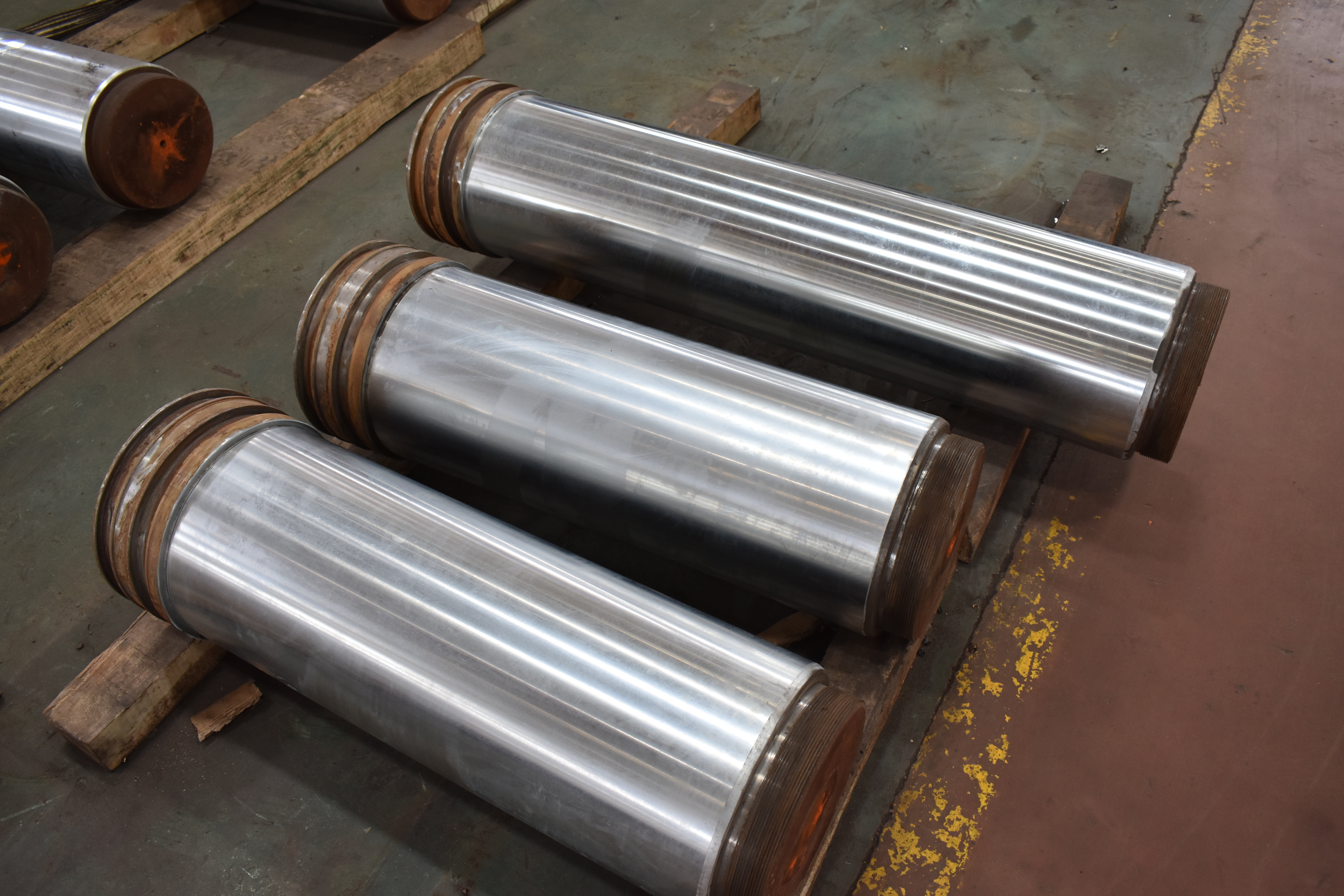

HYDRAULIC PRESS PISTON ROD

Medium-frequency hardening of 45 steel, deepening the material 2-3 mm, making the surface hardness of the piston rod to 55 ,effective solution to seal ring injury,not easy to scratch.

HYDRAULIC PRESS SEAL GROOVE

After rough machining on an ordinary lathe and finishing by a CNC lathe, the R angle is processed more smoothly, the quality is completely uniform, and the seal is tight and difficult to leak.

PREFILL VALVE

Adopt the new YCF1 series filling valve, advantages:

1 .improve the pressure relief response time and reduce noise.

2 .Low opening pressure, good self-priming performance and reliable reset.

4Compact structure, easy to install and use.

3 .flow channel design is smooth, small flow resistance.

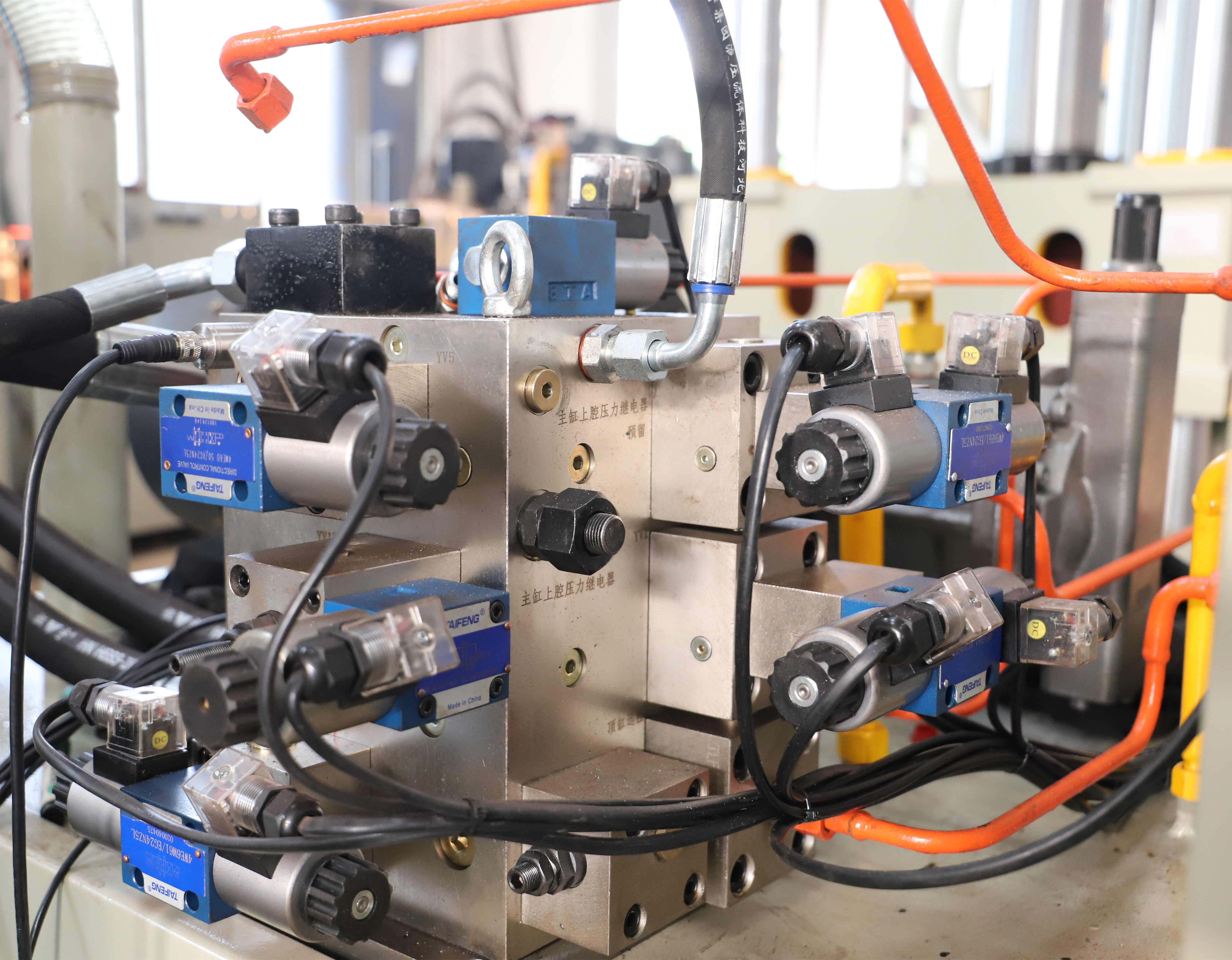

CARTRIDGE VALVE SYSTEY

The cartridge valve is inteqrated into the system to reduce leakagepoints, reliable operation and long service life.

THE PRESSURE MEASURING LINE

The pressure line is connected by hard pipe, which has the advantages of

1. Neat and beautiful;

2. Reduce the impact on the pipeline when the oil is pumped out, and it is more difficult to leak.

COMBINATION GASKET

All oil joints are sealed with a combination of gaskets, internally with rubber, externally with red copper customized by the manufacturer. Compared with the iron used by other manufacturers, the advantages are: 1.The ductility of red copper is strong, making the bond tight;2.In the process of high-pressure washing, red copper can effectively protect the rubber skin from breakage.

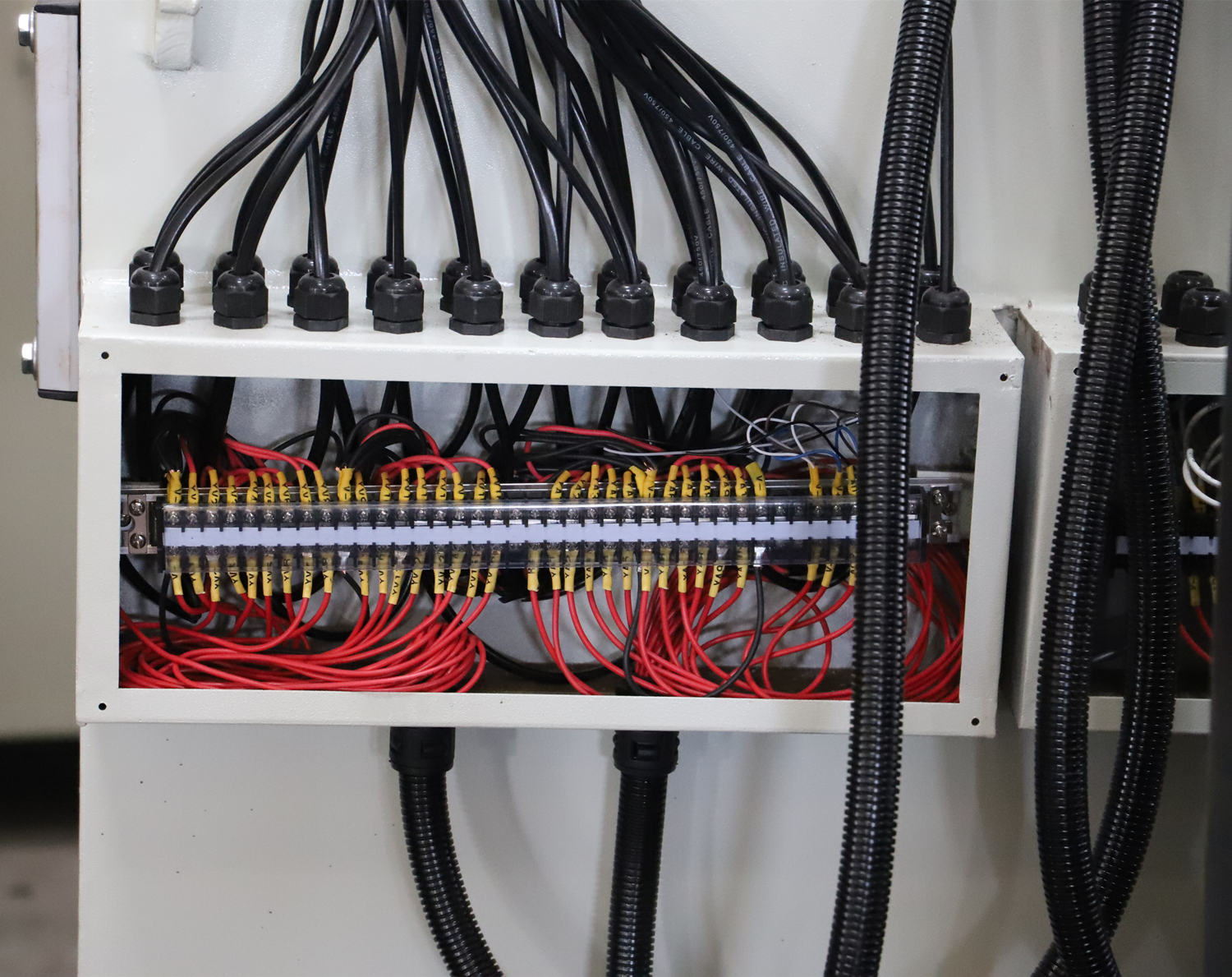

HYDRAULIC PRESS JUNCTION BOX

All the lines of the hydraulic system are concentrated in a junction box, which is introduced into the power cabinet or operation console through the aviation plug as a main line.

PLC PROGRAMMABKE CONTROL SYSTEM OPTIONAL

Compared with traditional relays,

1.The PLC has the characteristics of strong control reliability, simple wiring, easy programming, and convenient use.

2. The PLC has the small size, light weight, low power consumption, very power saving.

SERVO SYSTEM OPTIONAL

That is the hybrid drive technology, the hydraulic actuator has stable transmission and strong anti-interference ability, especially at low speed, it can improve efficiency, save a lot of electricity costs, and obtain higher product quality.

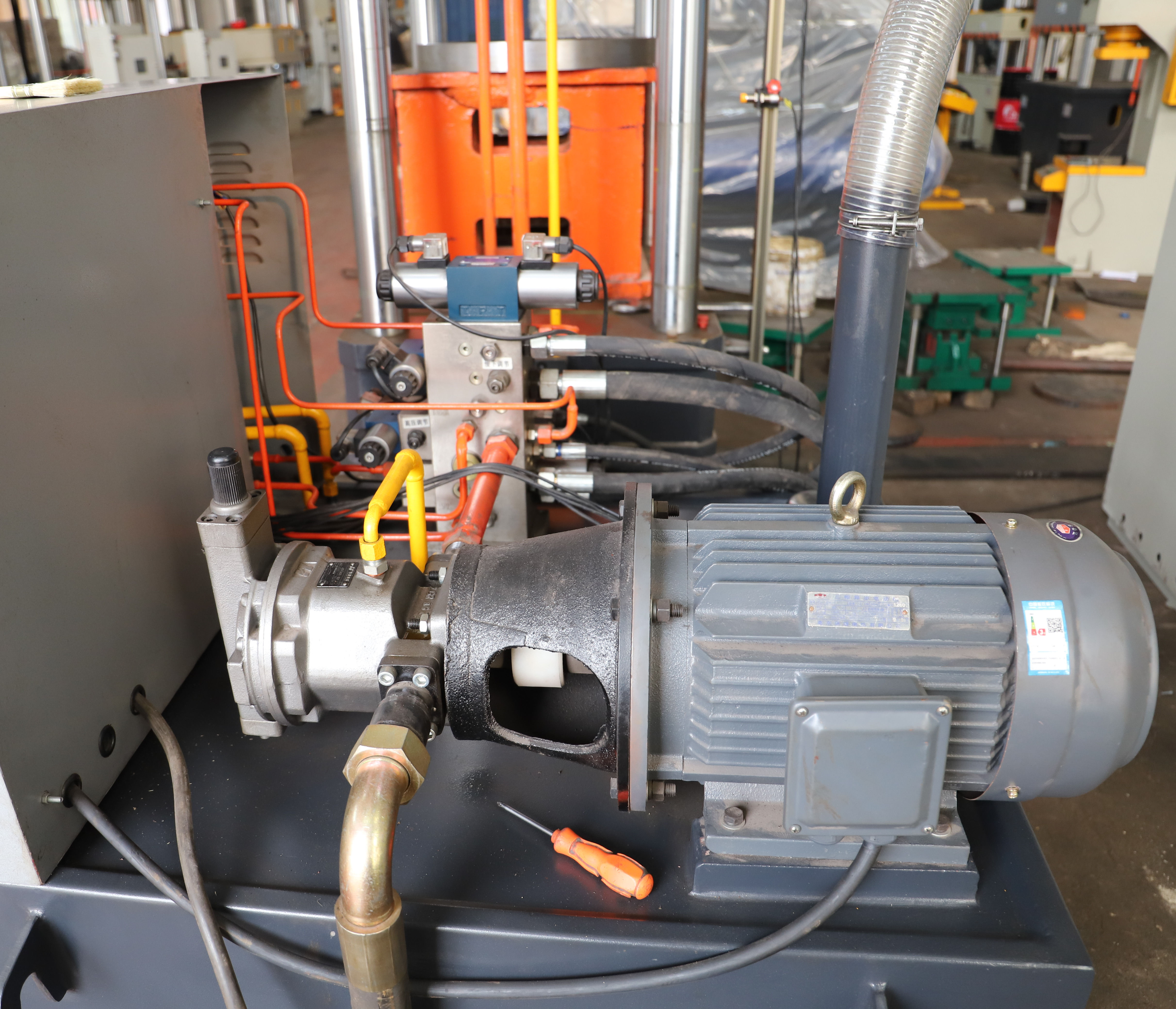

HYDRAULIC STATION LAYOUT

Compared with the plug-in oil pump,We use the external and horizontal position of the oil pump to reduce the heat generated when the oil is pumped out. The oil rises slowly, and the oil temperature is always controlled within a controllable range of about 55 degrees Celsius, so that the hydraulic components can work at a tolerable temperature and prolong the service life of the machine.

OIL PRESSURE PUMP(updated from YCY to SY)

1. Flange connection,

Good sealing effect, not easy to leak,

OIL PRESSURE PUMP

2. Nine plunger design,

When the workpiece is finely processed, the oil supply density is high, and the oil pump runs more stable and generates less heat.

HYDRAULIC PRESS TANK

Shot blasting combines three new processes of high-pressure vacuuming dough clearance.After the equipment is commissioned, the fuel tank is opened again, and the hydraulic oil flows into the main tank through the high pressure, and the components of each part are cleaned twice.

Payment Terms︰ TT / LC

Product Image